Company workshop "5S" rectification activities documentary

Date:2024-10-15With the increasingly fierce market competition, the company's management requirements for the production site are becoming higher and higher. In order to improve production efficiency, ensure product quality and create a clean and orderly working environment, our company decided to carry out "5S" rectification activities for half a month in the resin workshop, complete set workshop and arrester workshop.

"5S" management originated in Japan, is the cornerstone of modern enterprise site management, including finishing, rectification, cleaning, cleaning, literacy five aspects. These five aspects are interrelated and promote each other, and together constitute a complete system of site management. Through the implementation of "5S" management, it aims to eliminate on-site waste, improve efficiency, reduce costs, and improve employee literacy, so as to create greater value for the enterprise.

At the beginning of the rectification activities, each workshop set up a "5S" rectification team led by the workshop director, defined the rectification objectives, formulated a detailed rectification plan, and organized the training of new employees and lean improvement team members to ensure that each employee can deeply understand the connotation and requirements of "5S" management.

In the finishing stage, each workshop carried out a comprehensive inventory of the site, cleaned up the items that were no longer used, classified and stored the items that were used less frequently, and rationally partitioned the site to make the function of each area clear and the layout reasonable. Through the consolidation, the site space has been effectively used, and the working environment has been significantly improved.

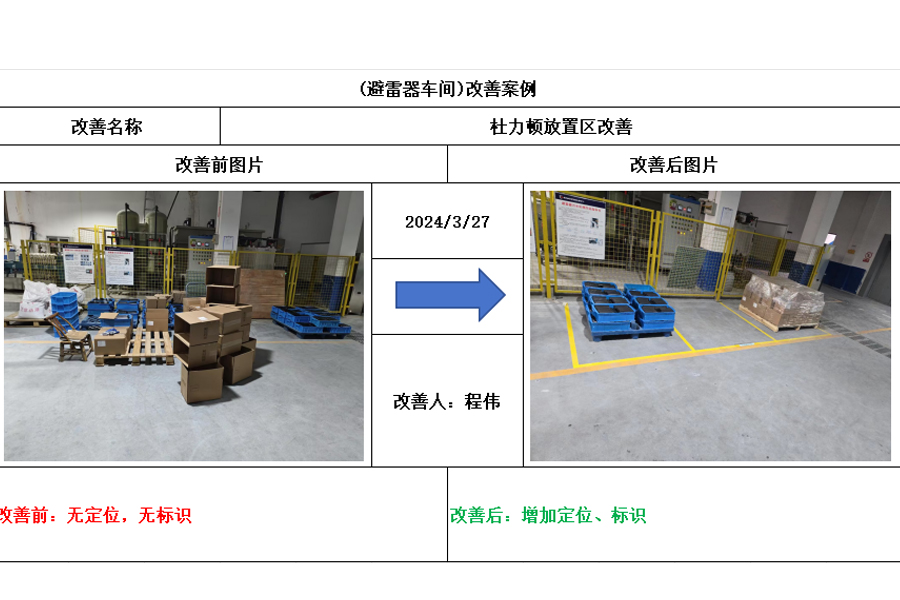

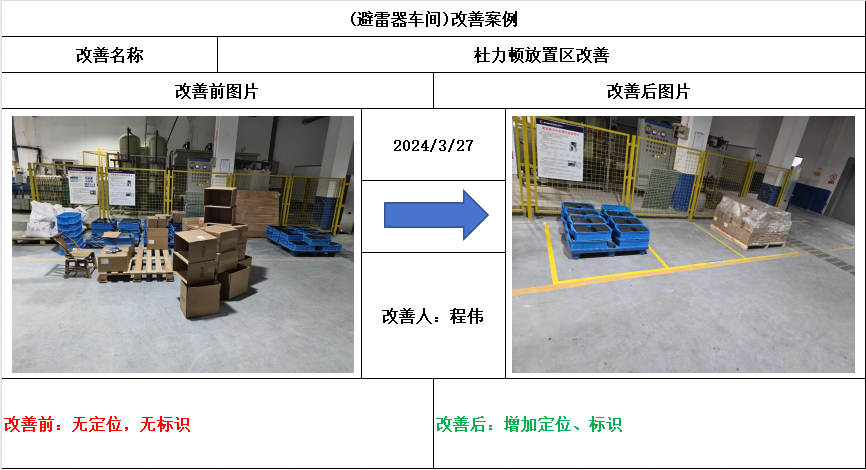

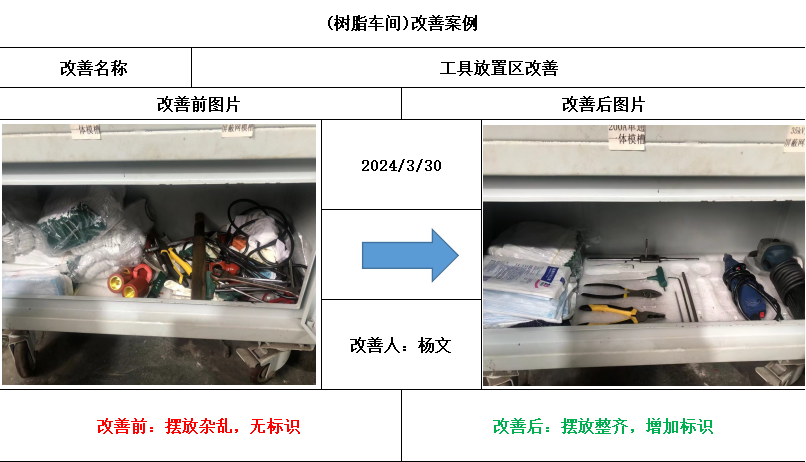

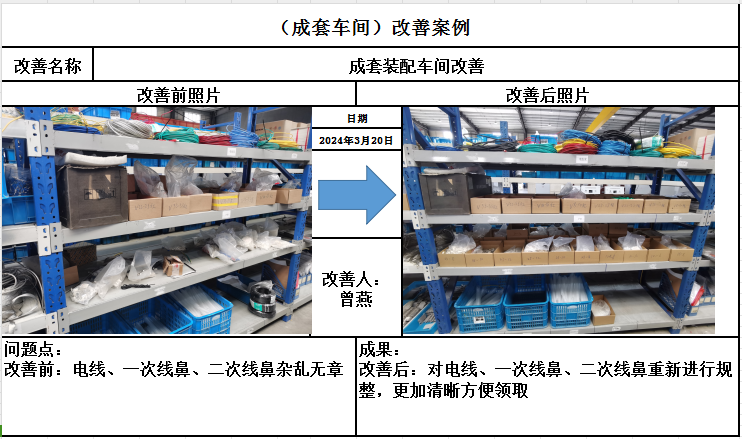

In the rectification stage, each workshop carried out fixed management of the on-site items, marked the name, quantity and storage location for each item, and formulated detailed operation instructions and operating procedures. Through reorganization, employees can quickly find what they need, reducing search time and improving work efficiency.

In the cleaning and cleaning stage, the workshops organized the relevant personnel to participate in the cleaning activities, thoroughly cleaned the equipment, the ground, the walls, etc., and eliminated the health dead Angle. At the same time, the cleaning responsibility system is established according to the visual maintenance standard, and the cleaning area and cleaning standard are defined for each person to ensure that the site is always clean and tidy.

In the quality stage, we pay more attention to the standardization and standardization of employee behavior, as well as the improvement of teamwork spirit, and jointly create an efficient and orderly production environment. Through the form of publicity column, we widely publicize the concept and requirements of 5S management, so that every employee can deeply understand and practice the spirit of 5S. We believe that through the joint efforts of everyone, our workshop will be able to glow with new vitality and vitality.

经过15天的紧张而有序的整改活动,三个车间的现场管理水平得到了显著提升。现场物品摆放有序、设备清洁完好、作业环境整洁明亮,员工的工作效率和质量也得到了明显提高。同时,员工的职业素养和团队精神也得到了有效提升,为企业的可持续发展奠定了坚实基础。

Any excellent management concept and action need to persevere and maintain, 5S activities follow-up maintenance inspection, not only to consolidate the early results, but also to strengthen the long-term management mechanism. Through the systematic inspection, we can find and solve the problems in the arrangement, rectification, cleaning, cleaning and literacy of the workshop in time to ensure that the requirements of 5S activities are truly implemented.

Although the "5S" rectification activity has achieved certain results, we are also clearly aware that site management is a long-term and arduous task, which requires continuous efforts and improvement of all employees. We will take this event as an opportunity to further deepen the "5S" management concept, constantly improve the site management system, and contribute to the sustainable and healthy development of the enterprise.

Looking forward to the future, we will continue to strengthen on-site management, promote the "5S" management concept into the hearts of the people, and constantly improve the core competitiveness of the enterprise and market position. We believe that with the joint efforts of all employees, our factory will be able to usher in a better tomorrow.

Related Recommendations

CN

CN ENG

ENG